- Home Page

- Company Profile

-

Our Products

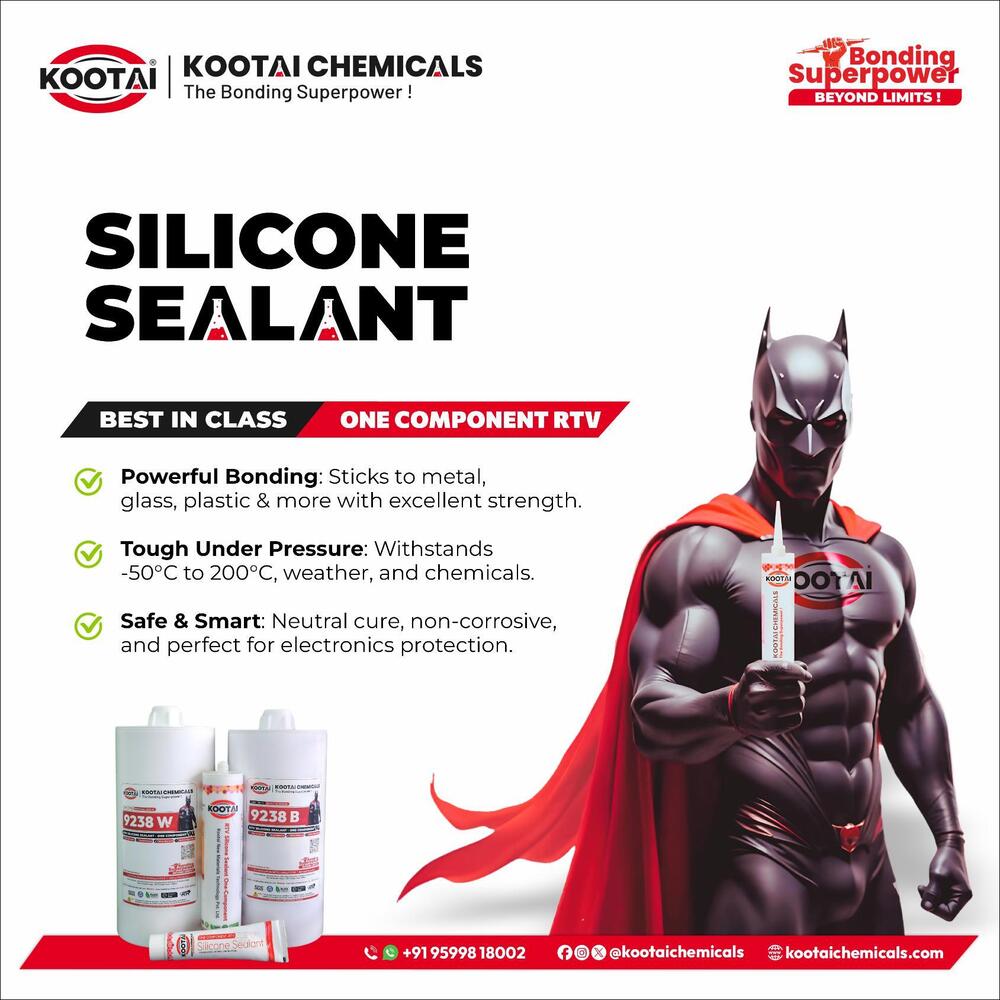

- Silicone Sealant

- RTV Silicone Sealant 9239 100ml

- RTV Silicone Sealant 9238B 300ml

- RTV Silicone Sealant 9238B 100ml

- RTV Silicone Sealant 9238W 2600ml

- RTV Silicone Sealant 9238B 2600ml

- RTV Silicone Sealant 9239 300ml

- 9238W 300 ML RTV Silicone Sealant

- One Component RTV Silicone Sealant - 9238W

- One Component RTV Silicone Sealant - 9238B

- One Component RTV Silicone Sealant- 9237W

- One Component RTV Silicone Sealant- 9237B

- One Component RTV Silicone Sealant- 9239

- One Component RTV Silicone Sealant (Translucent) - 9307TL

- RTV Silicone Sealant 9238W 300ml

- RTV Silicone Sealant 9238W 100ml

- RTV Silicone Sealant 9239 2600ml

- RTV Silicone Sealant 9307TL 2600ml I Translucent

- RTV Silicone Sealant 9307TL 300ml

- RTV Silicone Sealant 9307TL 100ml I Translucent

- Thermally Paste

- Silicone Potting

- Conformal Coating

- SMT Red Glue

- Solder Paste

- Cleaner Liquid

- Solder Flux

- Thermal Adhesives

- Glue Dispensing Machine

- Silicone Potting Compounds

- SMT Adhesives

- Industrial Cleaners

- Silicone Sealant

- Contact Us

RTV Silicone Sealant 9238B 100ml

109.0 INR/Tube

Product Details:

- Tensile Strength 2.1 Kilopascals (KPa)

- Surface Of Application Aluminum, Copper, Brass, Stainless Steel, Glass, ABS, PET, PC, PCB, Ceramics, Wood, some Plastics (except PE and PP).

- Holding Power 2.1 Kilopascals (KPa)

- Shelf Life 6 Months

- Form Paste

- Features -Specifically designed for bonding and fixing new energy sources, -Exceptional resistance to high and low temperatures (remains flexible at -50 C, elastic at +200 C) , -Excellent adhesion to most materials after curing -Non-toxic, odorless, non-corrosive, and environmentally friendly -Complies with RoHS Directive, -Maintains performance under extreme weathering and temperature conditions

- Hardness 65 Shore A

- Click to View more

X

RTV Silicone Sealant 9238B 100ml Price And Quantity

- 20 Piece

- 109.0 INR/Tube

- 42.00 - 45.00 INR/Tube

RTV Silicone Sealant 9238B 100ml Product Specifications

- Silicone

- Paste

- 100ml Tube

- Other

- Silicone-based, neutral-cure, moisture-curing, RTV (Room Temperature Vulcanizing) adhesive/sealant.

- Industrial Grade

- -Specifically designed for bonding and fixing new energy sources, -Exceptional resistance to high and low temperatures (remains flexible at -50 C, elastic at +200 C) , -Excellent adhesion to most materials after curing -Non-toxic, odorless, non-corrosive, and environmentally friendly -Complies with RoHS Directive, -Maintains performance under extreme weathering and temperature conditions

- CAS Numbers: 63148-62-9, 471-34-1, 21645-51-2, 1185-55-3, 68478-92-2, 2768-02-7

- Black

- Pure

- 2.1 Kilopascals (KPa)

- Aluminum, Copper, Brass, Stainless Steel, Glass, ABS, PET, PC, PCB, Ceramics, Wood, some Plastics (except PE and PP).

- 1 to 3 mm for bonding, sealing, and insulation in electronics, appliances, and general assembly. Millimeter (mm)

- 65 Shore A

- Other

- 20 Celsius (oC)

- 9238B silicone Sealant, 9238B RTV Silicone Sealant, 9238B One Compment RTV Silicone Sealant

- 2.1 Kilopascals (KPa)

- - Sealing and bonding in electronics and electrical devices - Waterproofing for enclosures and circuit housings - Dust and moisture barriers for industrial control units - Shock-absorbing layer for sensitive electronic modules - Adhesion where thermal cycling and flame resistance are crucial - Use in automotive, telecommunication, lighting, and power supply industries

- 6 Months

- Other

RTV Silicone Sealant 9238B 100ml Trade Information

- ICD Dadri (Greater Noida), India

- Letter of Credit (L/C), Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C)

- 5000 Piece Per Week

- 1 Days

- No

- Free samples are available

- 100ml Tube

- All India

Product Description

9238 RTV Silicone Adhesive is a one-component, room-temperature curing silicon elastomer designed for superior adhesion, insulation, and environmental resistance across a wide range of materials.

Kootai 9238 is a versatile one-part RTV (Room Temperature Vulcanizing) silicone elastomer engineered to meet industrial demands for bonding, sealing, and protection. It cures upon exposure to ambient moisture, creating a durable elastomer with exceptional adhesion to a variety of substrates including metals, ceramics, plastics, glass, and wood.

This neutral-cure formulation delivers excellent electrical insulation, thermal stability, and resistance to chemicals and weathering. 9238 is the ideal choice for applications requiring long-term performance in environments ranging from 50C to +200C. With excellent flame retardant and self-extinguishing properties, it also ensures safety where reliability under high temperatures is critical.

Features -

- Excellent Adhesion : Bonds well to metals, ceramics, plastics, glass, wood, etc.

- Neutral Cure System : Non-corrosive to substrates (releases alcohol vapors, not acetic acid).

- High Chemical Resistance & Weatherability : Stable under harsh environmental conditions.

- Superior Electrical Insulation Properties : Ideal for electronic and electrical applications.

- Wide Temperature Resistance : Operates from -50C to +200C.

- Self-Extinguishing : Offers flame retardant properties.

- One-Component System : Easy to apply without mixing.

- Room Temperature Vulcanizing (RTV) : Cures with moisture in the air at room temperature.

- Excellent Adhesion, Neutral Cure System, High Chemical Resistance & Weatherability, Superior Electrical Insulation Properties, Wide Temperature Resistance, Self-Extinguishing, One-Component System, Room Temperature Vulcanizing (RTV), Industrial Grade

Industrial Applications -

- Sealing and bonding in electronics and electrical devices

- Waterproofing for enclosures and circuit housings

- Dust and moisture barriers for industrial control units

- Shock-absorbing layer for sensitive electronic modules

- Adhesion where thermal cycling and flame resistance are crucial

- Use in automotive, telecommunication, lighting, and power supply industries

FAQs -

Q1: What materials does 9238 adhere to?

A1: 9238 exhibits excellent bonding with aluminum, stainless steel, copper, brass, glass, ABS, PET, and PCB. Moderate adhesion with PC and lower adhesion to PE/PP.

Q2: Does it require a primer?

A2: In most cases, primer is not needed. However, surface prep with a solvent like alcohol or xylene and testing on the target substrate is recommended.

Q3: How is it applied?

A3: It is dispensed directly from the cartridge. Once exposed to air, it begins curing and becomes tack-free in under 10 minutes at room temperature and 50% RH.

Q4: What are the available packaging sizes?

A4: It comes in 50ml, 100ml, 300ml, 2600ml, and 300kg bulk containers. Custom packaging is also available on request.

Q5: How should it be stored?

A5: Store in a cool, dry place under 25C. Keep away from direct sunlight and out of reach of children. Shelf life is 6 months.

Q6: Is it safe to use indoors?

A6: Yes, but ensure good ventilation. It releases alcohol vapors during curing, which should not be inhaled in high concentration

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email